This sequence is intended to answer one of the most commonly asked questions:

What do you actually do to the engine to rebuild it?

After dismantling, all parts are thoroughly cleaned and inspected. We use two BUPI cabinet washing machines for chemical cleaning. Both use bio degradable aqueous solutions to clean components after dismantling and more importantly after machining and prior to painting.

A Hodge Clemco bead blasting machine is used for components that require more intense cleaning than the cabinet washers can provide. Such as corroded engine covers, carbonised cylinder heads etc.

Engine Components in BUPI Washing Machine Basket

Large and smaller engine components (in baskets) after initial cleaning. A this stage, any damaged or scrap components can be rejected. Cleaned parts such as cylinder blocks and crankshafts are subject to non-destructive testing processes (crack and pressure test). Parts such as gaskets, core plugs, pistons, seals, bearings etc have been disposed of by this stage.

A Key Place to Reconditioned Engines: the Machine Shop

Components subject to machining operations such as cylinder blocks, cylinder heads, crankshafts, connecting rods, rockers etc travel through the machine shop under the control of our quality assurance system.

It is an essential stage to our reconditioning process, ensuring that any TD5, 300TDi or Land Rover engine meet the highest quality requirements.

4 Cylinder Block Casting - Cleaning

V8 Block Casting Remanufacturing Process

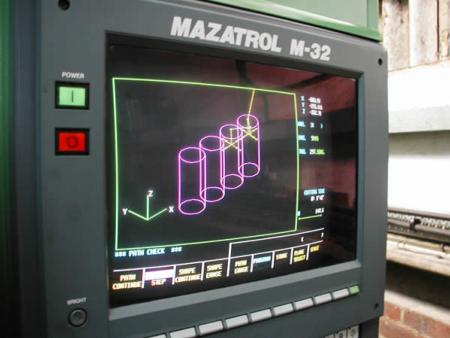

The CNC Machining is the Most Accurate Process Available

The machine is a Mazak AJV 25/405N CNC jig borer. This machine was purchased new in the early 90's with a view to improve accuracy in machining and reducing time cycles on complex machining operations and is a vital part in our engine production.

Machining Centre Mazatrol M-32 Display

Renishaw Probing

To Rebuild our Engines, we Use the AMC1200U Crankshaft Grinder

Reground Three Main Bearing Petrol Journal

AMC H260A Vertical Honing Machine

A Close Up of the Sunnen CK3000 Honing Head

This CNC Honing Machine is currently Dedicated to our V8 Engine Block Production

Close up of the two stage diamond honing machine.

Close up of the control system. This control system allows the shape and size of the cylinder bore to be monitored as the cylinder is being honed.

Sunnen C100A Horizontal Line Honing Machine

300TDi Cylinder Block - Finished

The Cylinder Head Department

We have supplied some of 10 000+ cylinder heads for exchange and our re-manufactured engine program.

Serdi 50 in Action Cutting a Valve Seat with Three Angled Seat Cutter

A 2.25 Petrol Cylinder Head Assembled with New Valves and Springs

A selection of Petrol and Diesle cylinder heads, ready for service.

Thanks for your Interest in Turner Engineering!